Power Inductors & Chokes

Power conductors are used to store or transfer energy in a magnetic field when current flows through your electrical circuit. When you need a custom inductor for applications that can store energy and filter and stabilize voltages, General Transformer Corporation is your best resource for design and development. We offer custom designed, laminated, toroidal, and cut core inductors to meet your application requirements. Our team of engineering experts has the skill set and ISO 9001 certified manufacturing capabilities to turn your inductor design dream into a reality.

Learn more about our custom power inductors & chokes below, Contact GTC to learn more about our design capabilities, custom manufacturing services, and other power solutions. Request a quote to begin your custom order.

Custom Inductors & Chokes

We design and manufacture inductors with toroid or laminated steel cores, multiple windings, taps, and other features as required for your specific application, per your exact specifications. Available core configurations include:

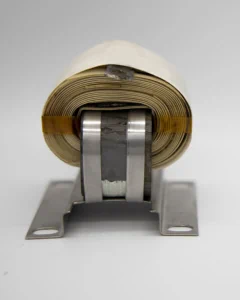

Laminated Inductors

The most common and generally most cost-effective construction, laminated core inductors are useful for a broad range of power and current levels. Laminated inductors feature a series of sheets to form a core. This core helps block eddy currents while minimizing energy loss.

Toroidal Inductors

Toroidal core inductors are compact, quiet, and efficient, especially at low to moderate power and current ratings. Toroidal inductors feature an iron core encased in wire and minimize stray magnetic fields for sensitive equipment. These inductors utilize a closed loop shape to create strong magnetic fields.

C Core Inductors

C core, also known as cut core, inductors provide many of the advantages of toroids, including low losses, high efficiency, and reduced acoustic noise for higher power and current requirements. C core inductors utilize a laminated steel toroidal core to shift a large amount of power without getting overheated. These inductors are ideal for applications requiring many transformers in non-standard sizes.

Choke Inductors

Chokes feature a donut shaped core with an insulated core wrapped around it and are used to filter out line noise. Chokes perform a similar task to inductors by restricting high frequency alternating currents while protecting insulation from damaging increases in circuit currents. Whereas an inductor can generate magnetic fields, a choke is used to remove AC Current and pass DC Current.

Request Custom Inductors & Chokes

Applications

In DC circuits, inductors are commonly used for filtering, allowing smooth DC current flow while blocking AC. In such applications, they are sometimes called chokes. In AC circuits, custom inductors are used for filtering, noise reduction, power factor correction, and many other purposes, and are sometimes referred to as reactors.

Custom inductors are suitable for both high voltage and high current applications. They can be found in:

- Sensors

- Tuning circuits

- Energy storage

- Motor drives

- Rectifiers

- Power supplies

- Battery chargers

Design Considerations For Choosing an Inductor

It is imperative to select the right inductor for your application to ensure that current flow is properly regulated. The correct inductor ensures optimal performance and longevity in your circuit. When designing an inductor, you should consider:

- Materials Used: Your core material determines energy loss, energy storage, inductance, and stability. Your core can be constructed from steel, nickel, and additional materials depending on your application.

- Coil Winding: Wire material, size, shape, and pattern determine coil losses, and should be considered when designing an inductor.

- Packaging: Inductors feature different sealing or packaging processes depending on vibration, temperature, and other application specific conditions.

Why Choose GTC

Original equipment manufacturers require reliable power inductors they can trust. For over forty years, General Transformer Corporation has been an industry leader in designing and engineering inductors that meet your specifications and exceed your expectations. Whether you require a new inductor or are looking to enhance your operations by replacing an existing one, GTC is ready to be a full-service partner to any OEM.

We are an ISO 9001:2015 certified manufacturer, carrying out all our services at our facility in Wylie, Texas. Our materials and supplies come exclusively from domestic suppliers within our trusted supply chain network. We ensure American-made quality on all orders and guarantee highly accurate power transformers at competitive prices delivered on time.

Contact General Transformer for Custom Inductors Today

We will work closely with you to ensure all your design needs are met. For more information about our inductors, or to discuss a custom inductor for your application, contact us with your design requirements today.